Polymers

Poly(Acrylic Acid)

What is PAA?

Poly(acrylic acid) (PAA) is a high-purity, water-soluble, anionic polymer designed for performance across electronic materials, life sciences, and industrial applications. Rich in carboxylic acid groups, PAA provides exceptional hydrophilicity, pH-responsive behavior, metal-ion chelation, and tunable rheological properties.

Our collection of PAA includes precisely controlled molecular-weight grades, from low to ultra-high MW, along with low-metal, semiconductor-compatible formulations ideal for advanced electronic materials.

Key Properties of PAA

PAA combines a unique set of physicochemical characteristics valuable across research, manufacturing, and high-performance materials:

- Anionic & highly hydrophilic: excellent compatibility with aqueous systems

- Precise molecular-weight control: available from low to ultra-high MW

- pH-responsive behavior: tunable swelling, rheology, and functional performance

- High-purity options: low-metal content for semiconductor and CMP applications

- Strong metal-ion chelation via dense carboxyl functionality

- Forms stable hydrogels and polyelectrolyte complexes

- Excellent adhesion to hydrophilic and inorganic surfaces

Applications of PAA

Electronic Materials

- CMP slurries & post-CMP cleaners: dispersant, stabilizer, rheology modifier, complexing agent

- Electronic packaging materials: adhesion control, viscosity tuning, residue control

- Low-metal formulations: suitable for semiconductor process chemistries

Materials Science & Polymer Engineering

- Superabsorbent polymers (SAPs)

- Hydrogels and swelling networks

- Polyelectrolyte complexes and thin films

- Coatings, adhesives, and sealants

Life Science & Biomedical Research

- pH-responsive hydrogels for tissue engineering

- Drug-delivery matrices with controlled release

- Surface coatings to modulate protein adsorption

- Polymer carriers for biosystems requiring aqueous compatibility

Industrial Applications

- Dispersants for pigments, fillers, and nanoparticles

- Scale inhibition in water treatment systems

- Viscosity and flow control in detergents, inks, and paints

PAA Frequently Asked Questions

What makes PAA suitable for CMP slurry and post-CMP formulations?

Its anionic, hydrophilic nature provides excellent dispersing, complexing, and rheology control—especially when using low-metal, high-purity grades optimized for semiconductor processes.

How does molecular weight affect PAA performance?

Lower MW enhances dispersing and complexation. Higher MW provides stronger thickening, adhesion, and hydrogel formation.

Is PAA biocompatible?

PAA is typically used in hydrogels, coatings, and controlled-release systems, though suitability depends on formulation and intended use.

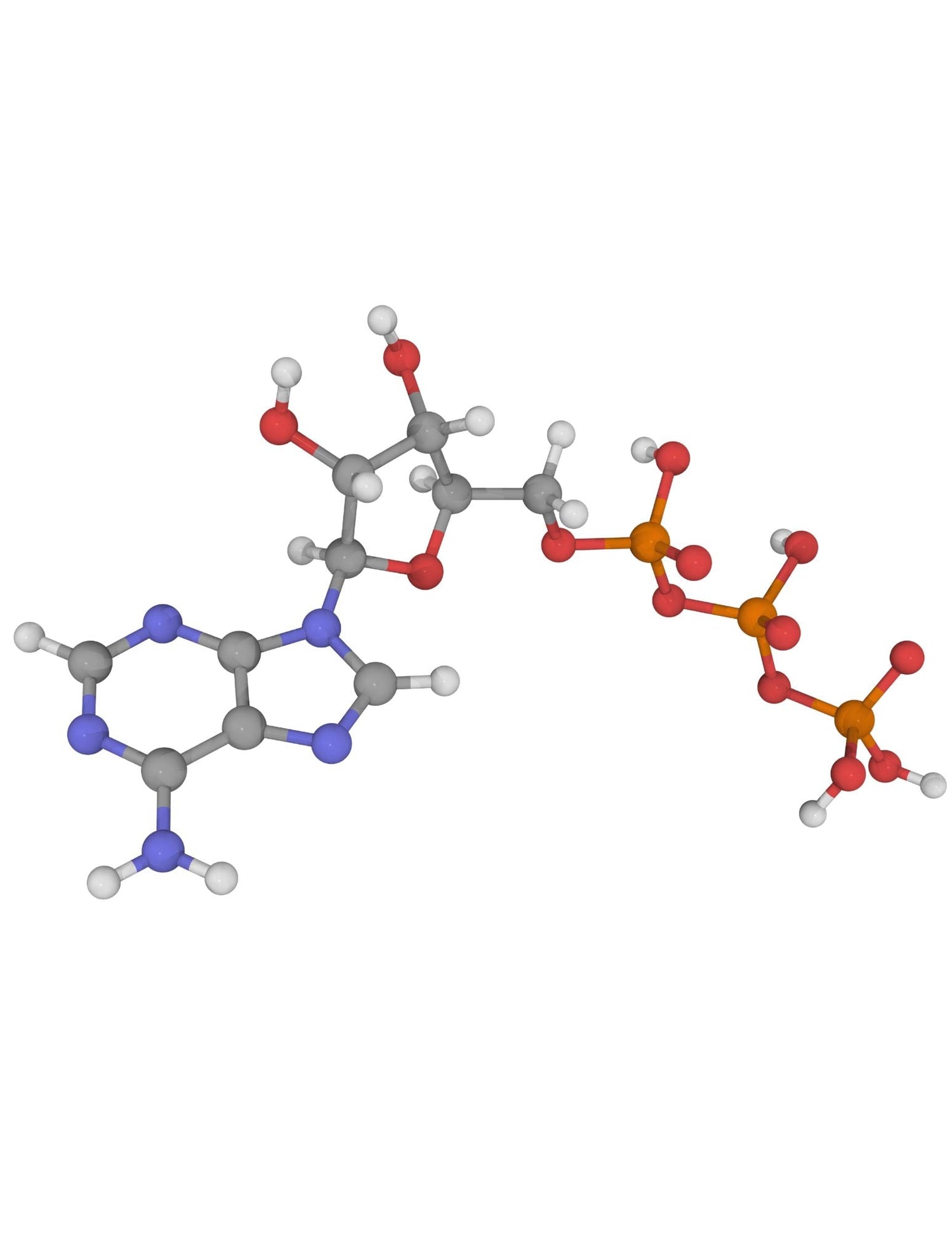

Why is PAA pH-responsive?

Its carboxylic acid groups ionize with increasing pH, resulting in swelling, viscosity changes, and tunable functional behavior.

What is the difference between PAA and sodium polyacrylate?

Sodium polyacrylate is the neutralized salt form, offering increased swelling and stability at neutral to high pH.